Photobioreactors (PBRs) are closed systems designed to cultivate microalgae and other photosynthetic microorganisms under controlled conditions. By providing a stable environment for microalgae growth, PBRs offer a more efficient and sustainable alternative to traditional open pond systems. Open photobioreactors, also known as open PBRs, are a new approach to algae cultivation that combines the advantages of both closed PBRs and open pond systems.

Types of Photobioreactors

There are several types of photobioreactors, each with its own set of advantages and disadvantages. The most common types include:

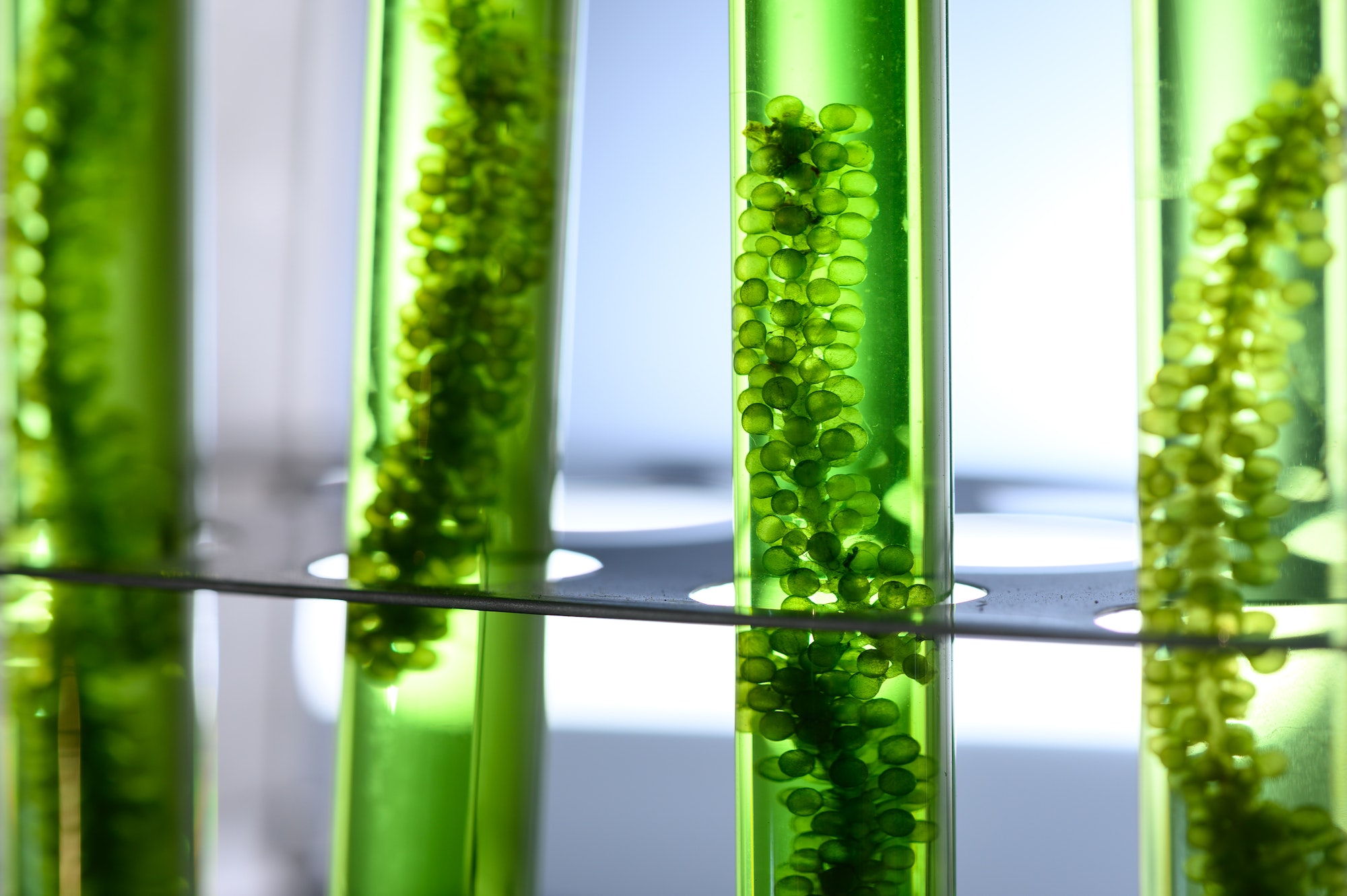

- Tubular PBRs: These systems consist of long transparent tubes where the algae culture is circulated. Tubular PBRs provide a large surface area for light exposure, which is essential for optimal algae growth. However, they can be expensive to build and maintain due to the need for continuous pumping and high energy consumption.

- Flat-panel PBRs: Flat-panel PBRs are made up of transparent panels through which the algae culture is circulated. They offer better light utilization compared to tubular PBRs, but they can be more expensive to build and maintain.

- Vertical-column PBRs: These systems use vertically oriented transparent columns or bags filled with algae culture. Vertical-column PBRs offer a large surface area for light exposure and can be relatively inexpensive to construct. However, they may require additional support structures and are prone to temperature fluctuations.

- Open photobioreactors: Open PBRs combine the benefits of closed PBR systems with the lower costs and simplicity of open pond systems. They generally consist of shallow ponds or channels with a transparent cover that allows sunlight penetration while reducing evaporation and contamination risks.

Photobioreactors: Harnessing Light for Algae Growth

The main advantage of using photobioreactors for algae cultivation is the ability to control and optimize the growth conditions, including light exposure. Algae, like other photosynthetic organisms, require light to produce energy through photosynthesis. In PBRs, the amount of light, its intensity, and the duration of exposure can be carefully controlled to maximize algae growth and productivity.

In open photobioreactors, the transparent cover not only allows sunlight to penetrate but also helps to create a greenhouse effect that maintains a stable temperature within the system. This is particularly important for microalgae species that are sensitive to temperature fluctuations.

Another advantage of using PBRs for algae cultivation is the possibility to optimize the culture medium composition. In closed systems, the nutrients and CO2 can be precisely supplied according to the needs of the microalgae species being cultivated. This enables higher biomass yields and better control over the quality of the final product.

Moreover, PBRs can prevent contamination from external sources such as predators, pathogens, and competing microorganisms. This results in a more consistent and pure biomass production compared to open pond systems.

Despite these advantages, there are some challenges associated with using PBRs for algae cultivation. One major challenge is scaling up the systems from laboratory-scale experiments to large-scale industrial production. The costs associated with constructing and maintaining large-scale PBRs can be prohibitive for some applications.

Additionally, the energy consumption associated with pumping and mixing in closed PBRs can be high, especially in large-scale systems. However, innovative designs and advancements in technology are helping to address these challenges and make photobioreactors a more viable option for large-scale algae cultivation.

In conclusion, open photobioreactors offer a promising approach for sustainable and efficient microalgae cultivation by combining the benefits of closed PBRs and open pond systems. With continued advancements in PBR design and technology, we can expect to see broader adoption of this innovative algae production method in various industries, including biofuels, pharmaceuticals, and food production.