Microalgae cultivation has gained significant attention in recent years due to its potential applications in various fields such as biofuels, pharmaceuticals, and nutrition. Among the different techniques available for algae cultivation, open pond systems are considered to be one of the most cost-effective and environmentally friendly methods. This article provides an overview of open pond systems for microalgae cultivation and highlights some of the key algae cultivation techniques that can be employed in these systems.

Open Pond Systems

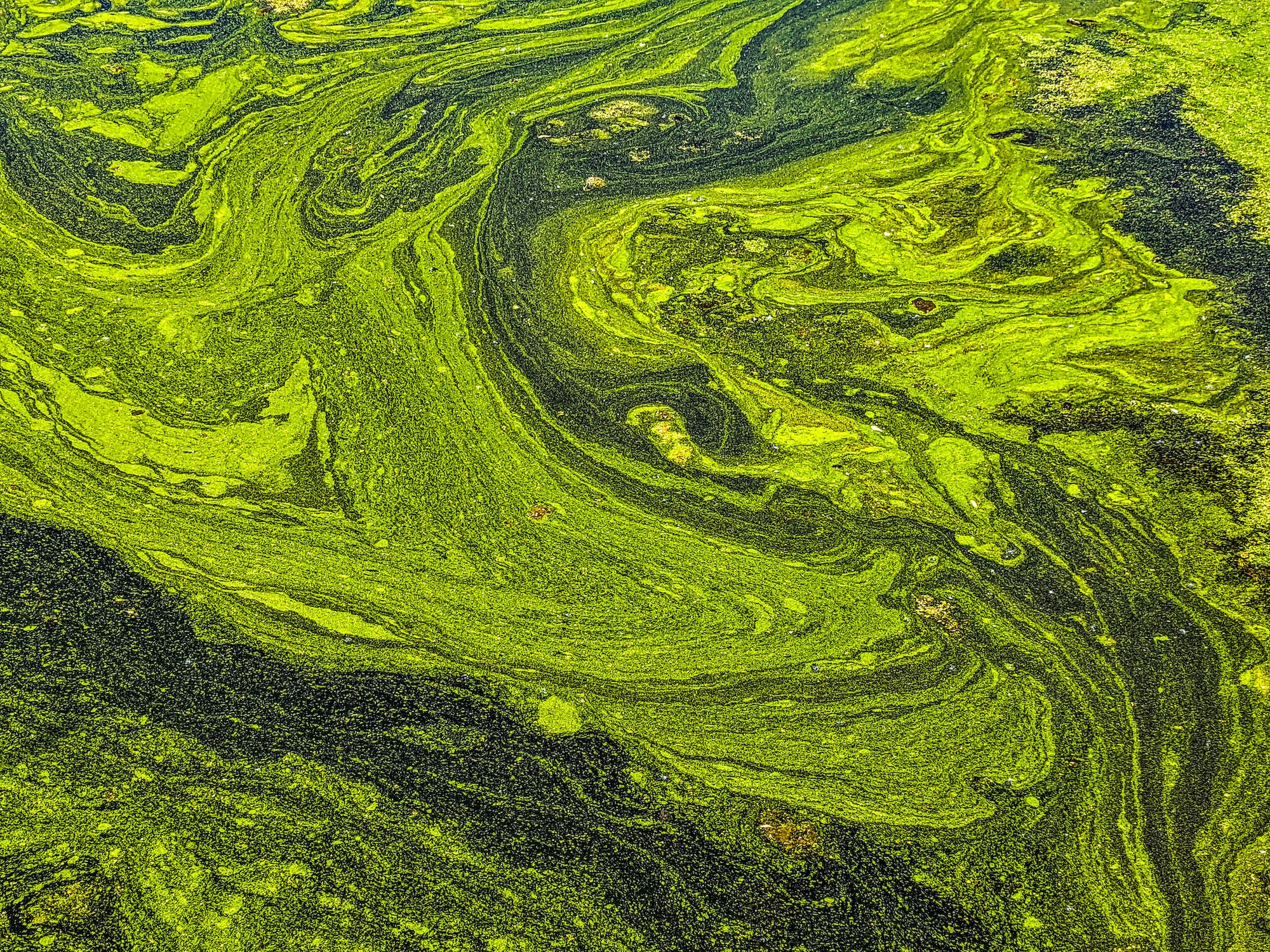

Open pond systems are large, shallow, outdoor ponds that are designed for the growth of microalgae. These ponds can range in size from a few square meters to several hectares, depending on the scale of production required. The main advantage of open pond systems is their low capital and operational costs compared to closed photobioreactors, which makes them an attractive option for large-scale commercial production of microalgae.

In open pond systems, microalgae are grown in a liquid medium, typically water mixed with nutrients and other essential elements required for their growth. The depth of the pond is usually maintained between 20 cm to 30 cm to ensure optimal light penetration and efficient photosynthesis. Paddle wheels or other mechanical devices are used to mix and circulate the culture medium to maintain homogeneity and prevent sedimentation of algae cells.

There are several types of open pond systems that can be used for microalgae cultivation, including raceway ponds, circular ponds, and inclined systems. Raceway ponds are the most common type used in commercial production due to their ease of construction and operation. These ponds consist of a series of parallel channels connected by curved sections at each end, allowing continuous circulation of the culture medium by paddle wheels.

Algae Cultivation Techniques

Several algae cultivation techniques can be employed in open pond systems to optimize the growth and productivity of microalgae:

- Selection of suitable microalgae strains: Choosing the right strain of microalgae is crucial for successful cultivation in open pond systems. Factors to consider when selecting a strain include the desired end-product, growth rate, tolerance to environmental conditions, and ease of harvesting.

- Optimization of culture conditions: The growth and productivity of microalgae can be significantly influenced by various environmental factors such as light, temperature, pH, and nutrient availability. By optimizing these factors, it is possible to achieve higher biomass production and better product yields.

- Use of CO2 supplementation: Microalgae require carbon dioxide (CO2) for photosynthesis, and providing an additional source of CO2 can help boost their growth rates. This can be achieved by bubbling CO2 gas directly into the pond or by using industrial waste gases that contain CO2 as a cheap and environmentally friendly alternative.

- Control of predators and pathogens: Open pond systems are prone to contamination by predators such as zooplankton and pathogens like bacteria and viruses, which can negatively impact the growth of microalgae. Implementing strategies to control these contaminants, such as regular monitoring, chemical treatments, or biological control agents, is essential for maintaining healthy cultures.

- Efficient harvesting and processing: Harvesting microalgae from open pond systems can be challenging due to their low cell densities and the presence of large volumes of water. Developing efficient harvesting techniques, such as sedimentation, flocculation, or filtration, is critical for reducing the costs associated with downstream processing and product recovery.

In conclusion, open pond systems offer a viable option for large-scale cultivation of microalgae due to their low capital and operational costs. By employing suitable algae cultivation techniques in these systems, it is possible to optimize the growth and productivity of microalgae for various applications in biofuels, pharmaceuticals, and nutrition. However, challenges related to environmental control, contamination management, and efficient harvesting still need to be addressed to fully realize the potential of open pond systems for microalgae production.